Domestic Auto Manufacturer Collapses Since the 1960s

Revised Article:

Struggling to Stay Afloat: The Plight of Small Automotive Suppliers in Our Country

The old adage that tradition guarantees success seems nothing more than a fairy tale these days. Another major automotive supplier from our home turf, operating since the '60s, has recently been forced to shut its doors. The once booming industry has taken a nasty turn, leaving many traditional companies gasping for breath.

Old-school companies, regardless of their industry, have been feeling the heat of escalating costs and the scarcity of skilled labor for quite some time now. And it’s not just the automotive sector - another supplier, holding onto a history of six decades, has fallen victim to the economic turn of events.

A Tale of Perseverance and Strategic Blunders

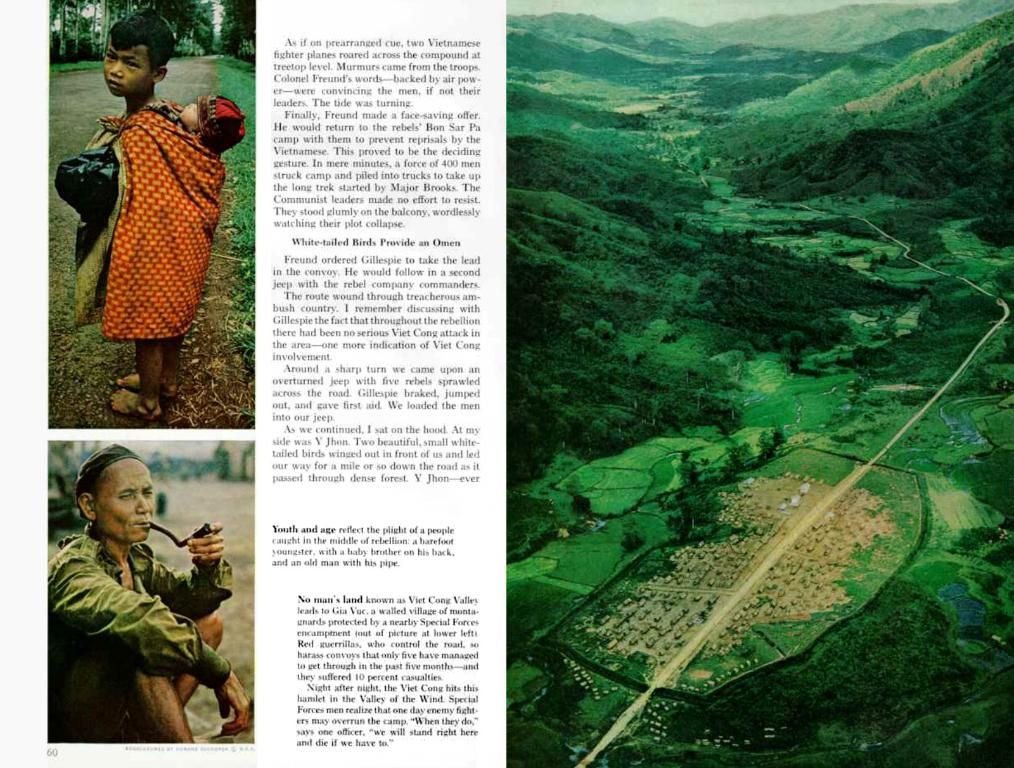

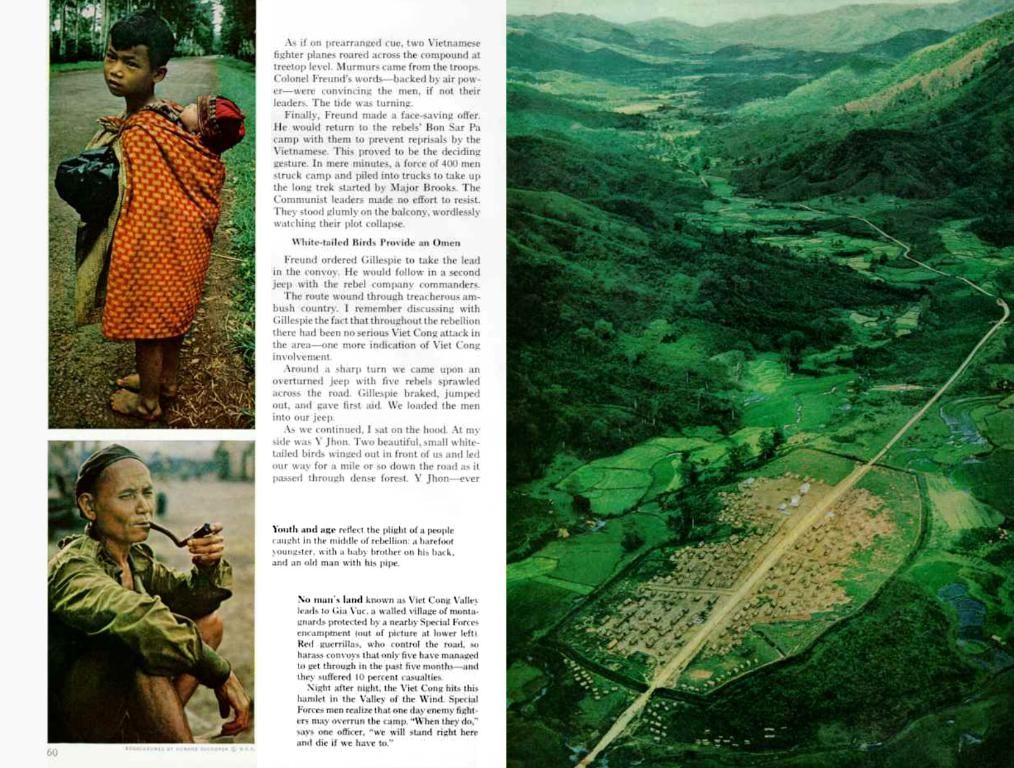

The story of Kick GmbH, a formerly niche supplier that expanded into the automotive industry, is a familiar one in German industrial culture - a tale of grit, vision, and a hint of misfortune. Established in 1960 by two Southern German tinkerers, the company started off producing plastic molds for toys. Fast-forward a few decades, and it had become a specialized supplier, churning out products for the automotive industry too. Based in Göppingen, the company maintained a low profile and a lean team of seven employees, mirroring the town's humble charm.

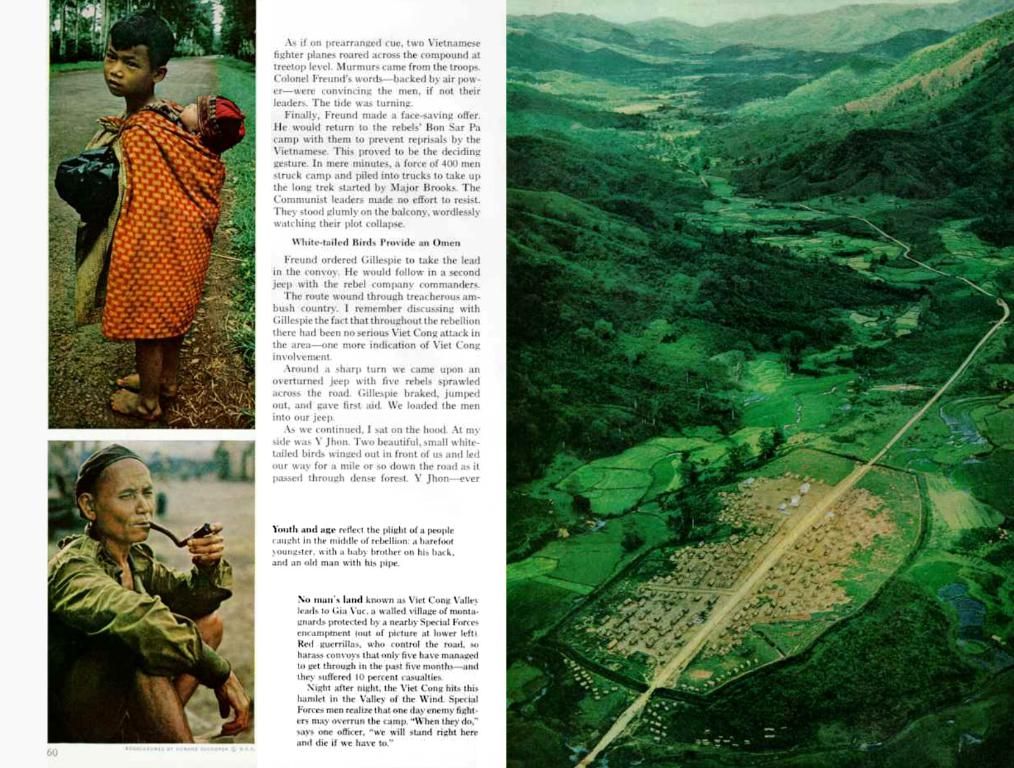

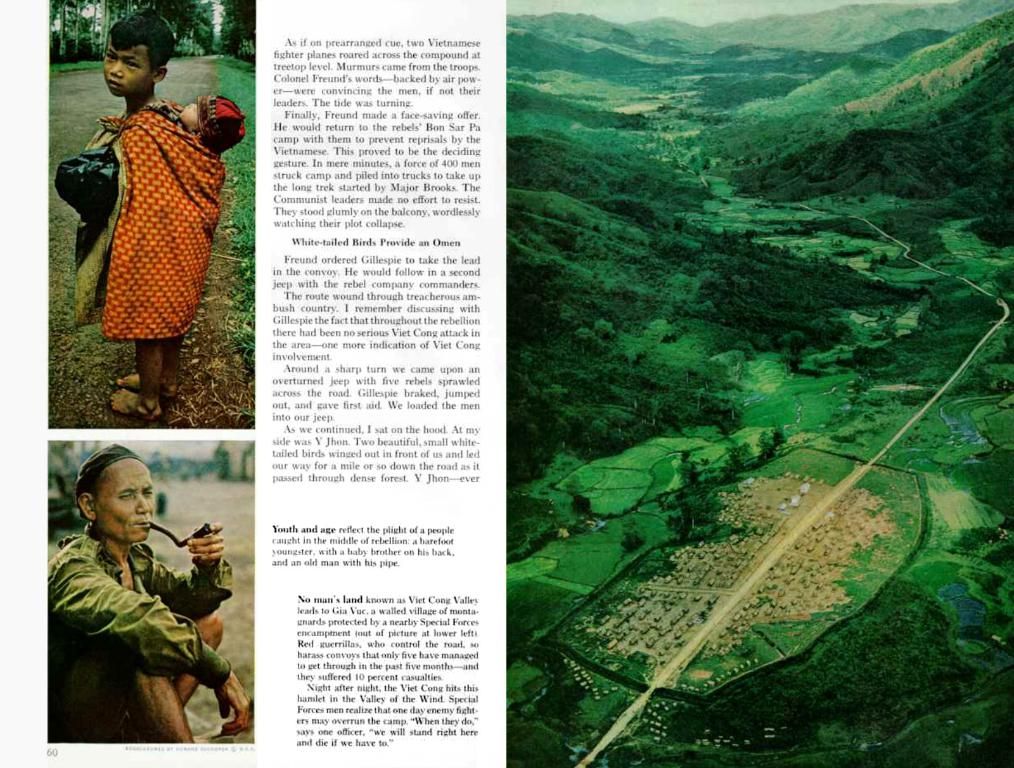

Times, however, have changed. With the rise in energy prices nearly doubling since 2022, and the COVID-19 pandemic sending shockwaves through the global supply chain, competition has become fiercer than ever. Around a quarter of SMEs are contemplating the idea of relocating their production overseas, even from Baden-Württemberg. For companies like Kick, with limited reserves, every hiccup in the market is a potential do-or-die situation. The region of Göppingen is not an exception to this norm; Kick represents just another chapter in German industrial history, teetering on the brink of extinction. The machines may still hum, the orders may still trickle in, but the future remains uncertain.

Dark Skies Ahead for Decades-Old Automotive Suppliers

On June 1, Kick GmbH took the first step towards insolvency. The insolvency administrator appointed to turn the company's fortunes around is now engaged in a desperate bid to find a purchaser or investor who can inject some much-needed capital. Wages are, for now, safeguarded through insolvency benefits. But whether Kick can rise from the ashes and return as a lean, modern provider remains to be seen.

Politicians and industry associations are offering their support – funding programs, tax deferrals, and export assistance are all intended to bolster the backbone of SMEs. Yet, a silver lining is not in sight. The automotive industry is undergoing seismic changes, moving towards electric mobility and digitalization – transformative efforts that require considerable investment. Smaller suppliers can struggle to keep pace, often lacking the necessary digital infrastructure. For Kick, this is a race against time – but it’s also an opportunity to reinvent itself as a nimble, tech-savvy provider.

Also Read:- Dark Clouds: Bottleneck Hits Mercedes – "Electric Cars Affected"- The Future of Decades-Old Automotive Suppliers: A Light at the End of the Tunnel?

Unexpected Challenges and Paths to Recovery

While the specifics of Kick GmbH's demise are unclear, common challenges faced by small automotive suppliers include:

- Supply Chain Disruptions: The global supply chain disruptions caused by factors like the pandemic and geopolitical tensions can result in production delays and increased costs for small suppliers.

- Technological Transition: The automotive industry is undergoing a rapid transformation towards electric vehicles and autonomous driving. Making the transition requires significant investment in new technologies and manufacturing processes – a challenge for smaller suppliers.

- Debt Management: Managing debt and ensuring cash flow can be a struggle for small suppliers, especially when faced with unexpected market changes.

- Market Competition: The fierce competition from larger, more diversified suppliers can make it difficult for smaller companies to secure contracts and maintain profitability.

Solutions for a Sustainable Tomorrow

To help small automotive suppliers stay afloat, several strategies are being explored:

- Government Support: Governments can offer subsidies or incentives for technologial upgrades and innovation, thereby helping smaller suppliers adapt to the new market conditions.

- Industry Partnerships: Collaborations between larger automotive firms and smaller suppliers can provide access to resources, expertise, and market opportunities that might not be available otherwise.

- Financial Assistance: Financial institutions can offer customized financial solutions, such as low-interest loans or restructuring options, to support suppliers in managing their debt and improving cash flow.

- Diversification: Encouraging suppliers to diversify their product offerings and customer base can help them reduce their dependence on a single market or client, making them more resilient against economic shocks.

A Bumpy Road Ahead

While Kick GmbH's story is unique, its struggles are emblematic of the challenges faced by small automotive suppliers across the globe. The road ahead may be long and fraught with obstacles, but with timely support and strategic changes, these suppliers could yet emerge stronger and more resilient.

- In light of the economic challenges faced by small automotive suppliers, such as Kick GmbH, it's crucial for the industry to explore solutions for sustainability, including government support, industry partnerships, financial assistance, and diversification.

- Other businesses, not limited to the automotive sector, are also grappling with escalating costs and the scarcity of skilled labor, as evidenced by the recent closure of another supplier with a history of six decades.